Testing Methods for Plastics fail quietly at first. A part looks fine, fits correctly, and even passes visual inspection—but under load, heat, or impact, it cracks, deforms, or loses strength. When that happens, the root cause almost always points to inadequate or incorrect testing.

That’s why understanding testing methods for plastics in chennai – Kiyo R&D LAB is important—not just for compliance, but for making confident material and design decisions.

Plastic testing is not a single test. It is a combination of methods, each revealing a different aspect of material behavior. Ignoring one category often means missing the real reason behind failures.

Plastics are used in:

Each application stresses plastic in a different way—tension, bending, impact, heat, chemicals, or long-term loading. No single test can capture all of this.

Proper testing methods for plastics in chennai – Kiyo R&D LAB ensure that:

Skipping or simplifying testing doesn’t reduce cost—it increases risk.

When companies search for this keyword, they’re usually asking:

At Kiyo R&D LAB, plastic testing is approached as a problem-solving process, not a checklist.

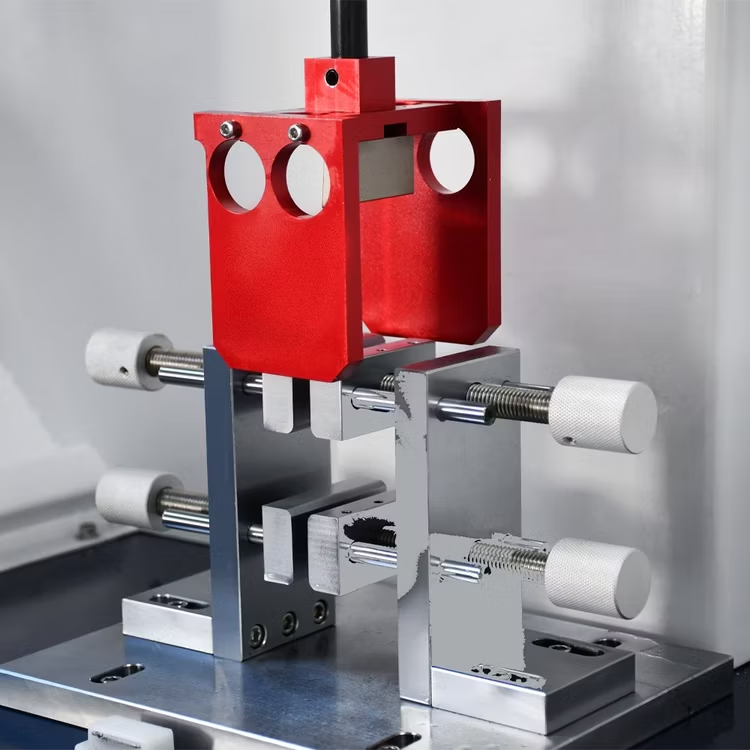

Mechanical tests evaluate how plastics behave under force and deformation. These are the most commonly requested testing methods.

Tensile testing measures how a plastic behaves when pulled until failure. It provides:

This test helps determine whether a plastic can withstand pulling forces during service or assembly.

Flexural testing evaluates bending behavior and stiffness. It is especially important for:

Flexural strength and modulus help predict deflection and bending failure.

Impact testing measures resistance to sudden shock loads. Many plastic failures occur due to impact—not slow loading.

Impact testing is critical for:

A plastic that performs well in tensile testing can still fail catastrophically on impact.

Hardness testing evaluates resistance to indentation. It is commonly used for:

Hardness does not replace strength testing, but it provides fast screening insight.

Heat is one of the most damaging factors for plastics. Thermal testing methods evaluate how plastics behave as temperature changes.

Thermal tests help determine:

This is critical for automotive, electrical, and outdoor products.

Some plastics degrade slowly under heat, losing strength over time. Thermal analysis helps identify:

This information cannot be obtained from mechanical tests alone.

Plastics often operate in environments involving:

Environmental and chemical resistance testing helps evaluate whether plastics retain their properties after exposure. Many real-world failures occur because environmental effects were not tested during validation.

Plastics must meet dimensional and physical requirements to function properly.

These testing methods help verify:

Dimensional changes due to heat or humidity can cause fitment issues and functional failure.

At Kiyo R&D LAB, plastic testing is not about running isolated tests. It is a structured workflow:

This approach ensures test results are meaningful—not misleading.

Testing methods for plastics are widely used for:

When suppliers claim the same plastic grade, testing often reveals differences in strength, toughness, or thermal behavior that datasheets hide.

When plastic parts fail unexpectedly, guessing the cause leads to wrong conclusions.

Plastic testing helps determine:

Testing data supports root-cause analysis and corrective action.

The testing methods for plastics in chennai – Kiyo R&D LAB support:

Each group uses testing differently—but accuracy matters to all.

A good test report should help you decide—not confuse you.

Effective reports include:

Kiyo R&D LAB focuses on clarity so results can be confidently shared with customers, auditors, and internal teams.

Plastics don’t fail randomly. They fail because their limits were not properly tested or understood.

Understanding and applying the right testing methods for plastics in chennai – Kiyo R&D LAB helps manufacturers reduce rejection, prevent field failures, and make informed material choices.

Testing is not an expense—it’s risk control.

When plastic performance matters, assumptions are costly. Proper testing turns uncertainty into confidence.