Hardness looks simple on paper. A single number. Shore A, Shore D, Rockwell, or IRHD.

But in real polymer hardness testing applications, hardness is never “just a number.” It controls fit, sealing force, wear resistance, tactile feel, noise, durability, and even long-term failure.

When hardness is wrong, parts don’t always break immediately. They leak, creep, wear, deform, or get rejected quietly—and by the time the issue is noticed, batches are already in the field.

That is exactly why polymer hardness testing services in Chennai – Kiyo R&D LAB are critical for manufacturers who care about performance, consistency, and customer acceptance.

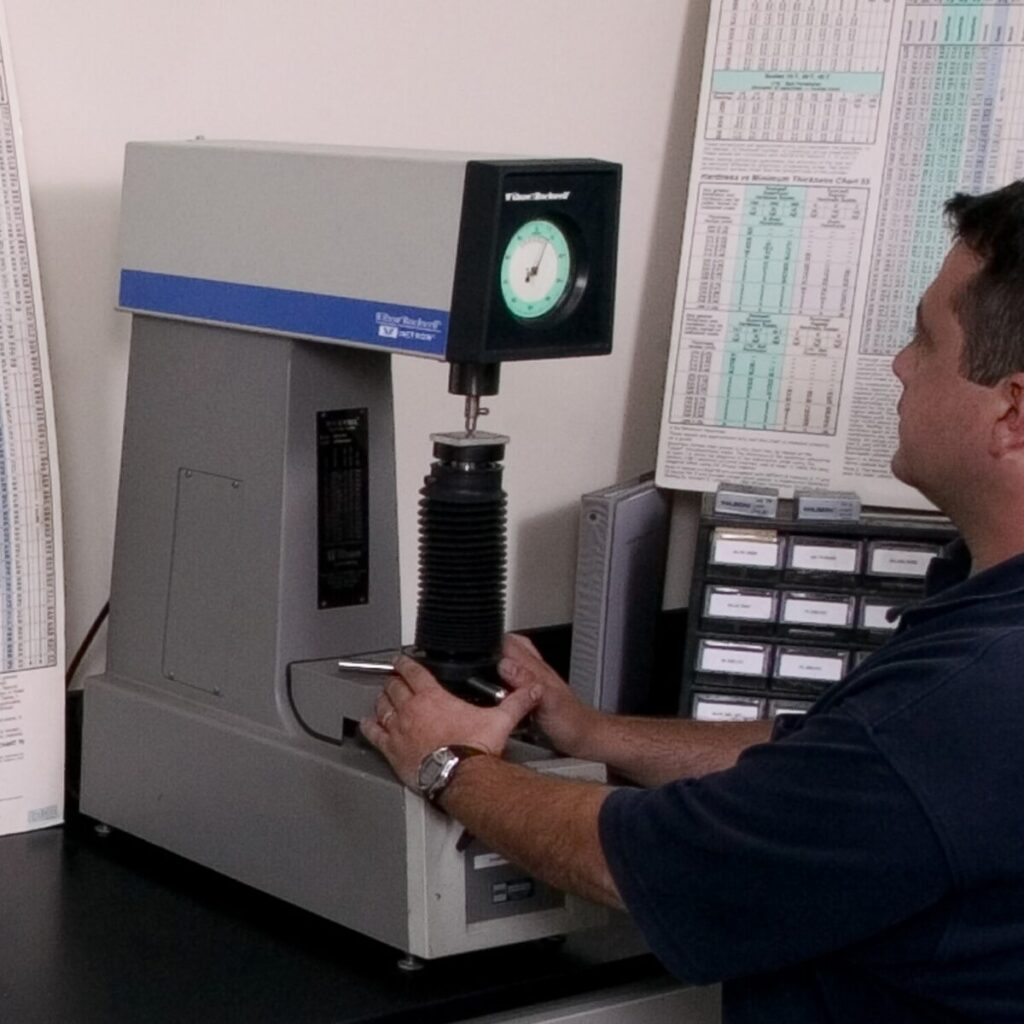

At Kiyo R&D LAB, hardness testing is not treated as a quick press-and-record activity. It is treated as a controlled evaluation of material behavior, tied directly to application requirements and real-world use.

Polymer hardness testing measures a material’s resistance to indentation under a defined load and geometry. In simple words, it tells you how soft or hard a polymer surface actually is.

But practically, hardness answers much bigger questions:

Hardness is often the first indicator of formulation drift or processing issues—long before visible failures occur.

Many teams rely on supplier datasheets for hardness values. That’s risky.

Why?

Two parts can look identical and still differ by 5–10 Shore points. That difference can decide whether a seal works—or fails.

This is why polymer hardness testing services in Chennai – Kiyo R&D LAB are used not only for certification, but for control and prevention.

Hardness testing at Kiyo R&D LAB supports a wide range of polymer materials, including:

Wherever possible, actual finished components are tested—because hardness on a plaque and hardness on a real part are not always the same.

Used primarily for soft polymers and elastomers such as rubber, flexible plastics, seals, and gaskets. Shore A directly impacts compression behavior, sealing force, and flexibility.

Used for harder plastics such as rigid thermoplastics and engineering polymers. Shore D values correlate with stiffness, scratch resistance, and surface durability.

Depending on application and specification, hardness evaluation may be aligned with customer or industry requirements for comparison and validation.

At Kiyo R&D LAB, the method is chosen based on material behavior and use-case, not convenience.

Hardness becomes powerful only when interpreted correctly.

For example:

This is why polymer hardness testing services in Chennai – Kiyo R&D LAB are often combined with:

Hardness is not isolated—it’s contextual.

Smart teams test hardness early, not after problems appear.

During product development, hardness testing helps:

Changing hardness after tooling is finalized is expensive. Testing early saves redesign cycles.

Batch-to-batch variation is one of the most common—and ignored—causes of polymer failures.

Hardness testing is often the fastest way to detect:

A simple hardness comparison between incoming batches can prevent weeks of downstream issues.

Polymers change with time. Heat, oils, fuels, and environment slowly alter hardness.

At Kiyo R&D LAB, hardness testing is frequently performed:

Hardness increase may indicate embrittlement.

Hardness decrease may indicate softening or chemical attack.

Both lead to failure—just in different ways.

Hardness testing without method control is meaningless. Kiyo R&D LAB performs hardness testing aligned with relevant ASTM, ISO, IS, or customer-specified procedures, depending on application needs.

Standards-based testing ensures:

Without standards, hardness numbers become arguments. With standards, they become evidence.

A useful hardness report clearly documents:

At Kiyo R&D LAB, reports are written so engineers and quality teams can act on the data, not just archive it.

Many labs can press a durometer. Fewer labs understand what the number means in real life.

Kiyo R&D LAB stands out because:

This approach prevents repeated failures caused by oversimplified testing.

Polymer hardness testing services in Chennai – Kiyo R&D LAB are essential for:

If hardness affects fit, sealing, durability, or wear—testing is not optional.

Hardness is one of the simplest polymer tests—and one of the most misunderstood. Used casually, it gives false confidence. Used correctly, it becomes a powerful control tool.

Polymer hardness testing services in Chennai – Kiyo R&D LAB turn hardness numbers into meaningful decisions—helping you prevent failures, control variation, and deliver consistent performance.

In polymer engineering, the difference between “acceptable” and “failed” is often just a few Shore points.