Packaging is not just a layer of protection. It is a silent quality-checker, a safety shield, and a brand promise that your product reaches the customer in perfect condition. Whether you manufacture foods, pharmaceuticals, cosmetics, chemicals, household goods, plastics, or industrial components, one weak point in packaging can lead to leaks, contamination, product failure, customer complaints—or even regulatory action.

This is where Package Integrity Testing Services @ Kiyo R&D LAB become essential. At Kiyo, we help manufacturers scientifically evaluate the strength, durability, sealing performance, and protective capability of their packaging materials. With NABL-aligned testing methods, advanced equipment, and fast turnaround, we support industries in delivering safe and reliable products to market.

Most brands underestimate the importance of packaging until something goes wrong. In reality, even the best materials can fail due to:

A reliable package must withstand stress, retain its seal, resist leaks, and preserve product quality throughout its life cycle. Package integrity testing ensures exactly that.

Package integrity testing involves a series of standardized scientific methods to evaluate:

At Kiyo R&D LAB, we test flexible packaging, rigid packaging, laminates, pouches, bottles, containers, blisters, sachets, plastic bags, medical packaging, and food packaging—across multiple industries.

Our laboratory provides a complete suite of integrity evaluations to ensure packaging performs reliably in real-world conditions.

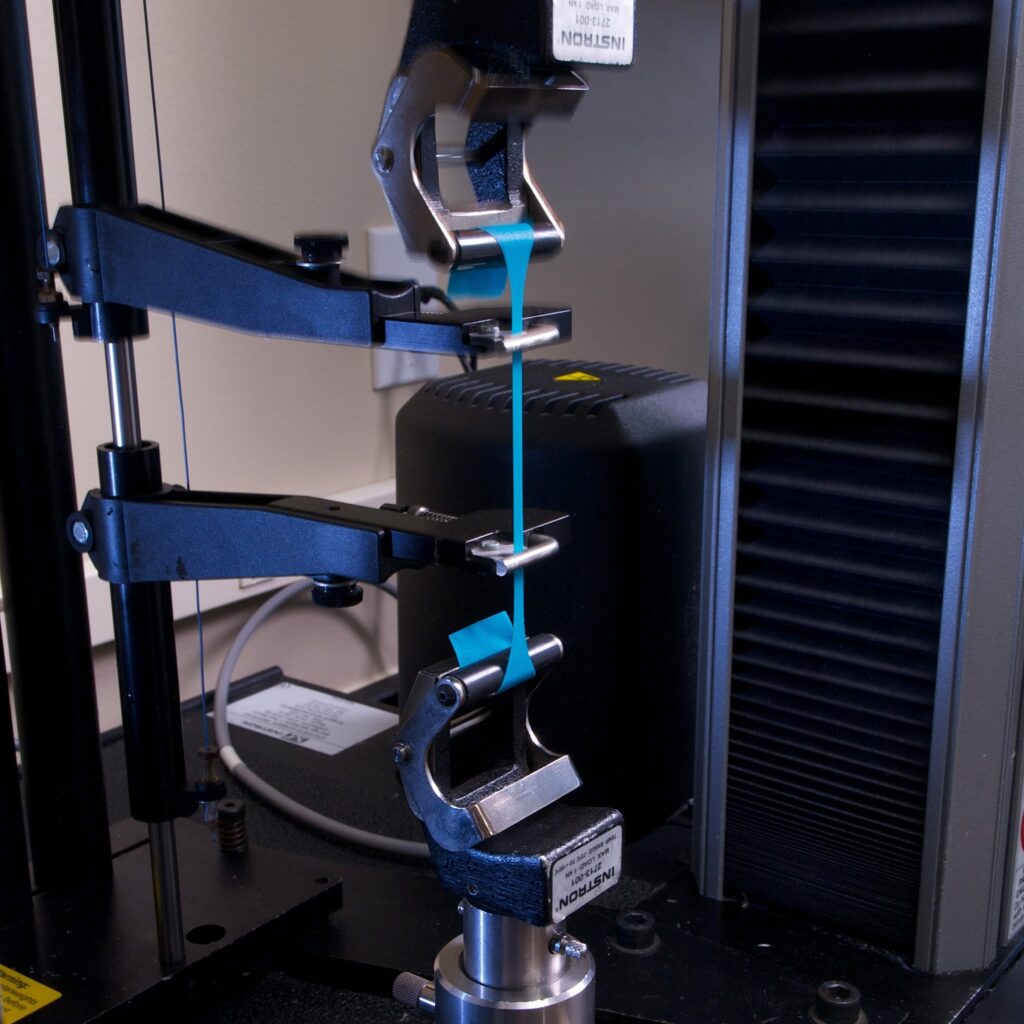

Seal strength determines how well the package seals hold under stress. Weak seals can easily open during transport, causing spoilage or spillage.

We evaluate seal performance based on:

Industries: Foods, beverages, pharma blister packs, sachets, PET bottle caps, 3-side seal pouches.

Leakage is the most common failure seen in pouches and containers. Kiyo performs advanced vacuum and pressure leak tests to ensure:

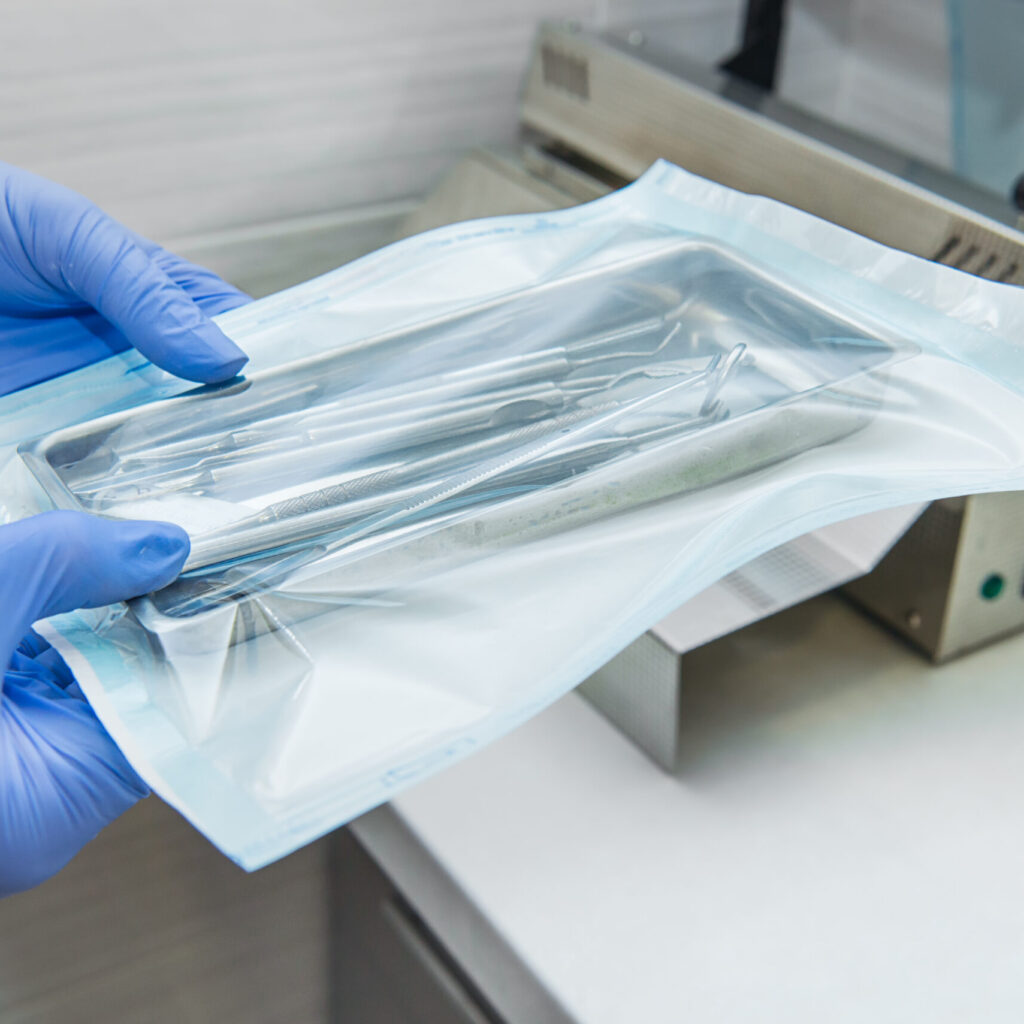

Leak testing is critical for sterile packaging, sealed liquids, medical devices, cosmetics, chemicals, and food pouches.

Burst testing checks how much internal pressure the packaging can withstand before it fails. This helps determine packaging stability during:

Applications: Milk packets, snack pouches, vacuum packs, chemical sachets.

Flexible packaging materials undergo mechanical stress during filling, sealing, stocking, and logistics.

We test:

These values reveal whether the film is suitable for heavy-duty or long-duration applications.

Product packages face multiple drops and impacts during transport. A small crack or deformity can compromise product integrity.

Kiyo simulates:

This ensures packaging survives real-world handling.

These tests help detect micro-leaks and structural weaknesses that are not visible to the naked eye.

Used widely for:

Packaging materials change behavior under:

Our conditioning chamber tests ensure packaging can handle diverse environments without losing integrity.

Kiyo R&D LAB supports every sector where packaging plays a critical role:

Whether you use LDPE, HDPE, PP, PET, laminates, blister packs, or paperboard, Kiyo ensures your packaging meets performance expectations.

You’re not hiring just a testing lab—you’re partnering with a team that takes your product quality personally.

Our procedures follow ASTM, ISO, and industry-standard methods to ensure regulatory compliance.

We use calibrated equipment and strict quality control for reliable test data.

Kiyo is recognized for fast turnaround supporting urgent production, QC needs, and project deadlines.

We help new brands validate packaging prototypes, reduce failures, and optimize cost.

Our experts explain test results, failure modes, and improvement actions clearly—no technical confusion.

Final-year engineering students receive 50% OFF + free consultation for packaging and material testing projects.

Manufacturers often discover issues only after a customer complaint. Kiyo helps detect problems early, such as:

Fixing these early saves money, brand reputation, and production time.

With clear insights from Package Integrity Testing Services @ Kiyo R&D LAB, brands can:

Better packaging = better customer experience.

In today’s competitive market, packaging is more than protection—it is your product’s first guarantee of quality. A leak, crack, or weak seal can destroy customer trust instantly. Package Integrity Testing Services @ Kiyo R&D LAB help you eliminate risks, validate packaging strength, and deliver your products safely to customers.

Whether you are a manufacturer, startup, exporter, or engineering student, Kiyo offers accurate testing, fast reporting, and technical support that keep your packaging reliable and compliant.

Your product deserves to be protected the right way.

Your packaging deserves to be tested by professionals.