Advanced Paint Impact Test Services in chennai

When you see a freshly painted car, machine, or metal structure, it’s easy to admire its glossy finish. But have you ever wondered how long that paint will stay intact when exposed to real-world wear and tear — like stone chips, impacts, or rough handling?

That’s where Paint Impact Test Services in India – Kiyo R&D Lab play a vital role. At Kiyo R&D Lab, we help manufacturers, OEMs, and product designers evaluate how well their paints and coatings can withstand sudden impact without cracking, flaking, or losing adhesion.

Our goal is simple — to ensure your coatings don’t just look great but stay strong and perform consistently throughout their lifecycle.

A paint impact test measures the ability of a coating to resist mechanical deformation or cracking when subjected to sudden impact.

In simple words, it simulates what happens when your painted surface gets hit by an object — for example, a small rock striking a car door, or a tool bumping into a coated machine part.

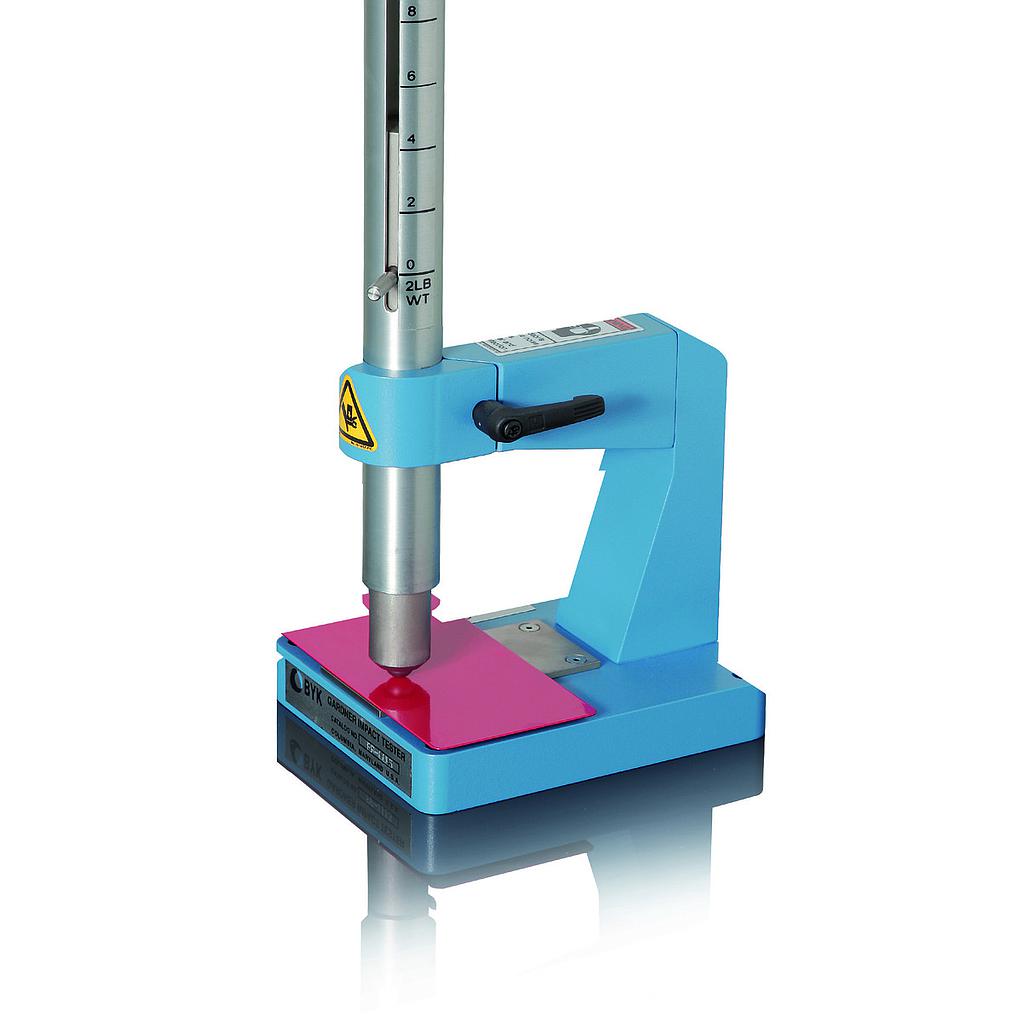

During the test, a known weight is dropped from a fixed height onto the painted surface. The resulting damage (if any) is then visually examined for cracks, delamination, or loss of gloss.

This test helps determine the impact resistance of paints and coatings — one of the most important parameters in evaluating coating durability.

Even the most advanced coatings can fail if they cannot handle everyday impact or stress. Cracks or chips on the surface are not just cosmetic issues — they can expose the base material to corrosion, reduce product lifespan, and lead to customer complaints.

By investing in paint impact testing, industries can:

For manufacturers in automotive, industrial, and appliance sectors, impact testing is a must-have in their quality assurance process.

When it comes to Paint Impact Test Services in India – Kiyo R&D Lab, our focus is precision, reliability, and meaningful reporting — not just numbers.

Here’s what makes Kiyo R&D Lab a trusted partner for industries across India:

We use standardized impact testers that conform to global test methods like ASTM D2794, ISO 6272, and IS 101 (Part 5/Sec 3) to deliver accurate, repeatable results.

Our materials scientists and coating specialists have years of experience in paint, polymer, and surface testing. They interpret data, analyze failure patterns, and help you understand what’s really happening beneath the surface.

Every report includes detailed test parameters, photos, visual observations, pass/fail outcomes, and expert recommendations for improvement.

We know time matters. That’s why Kiyo R&D Lab ensures quick sample processing and reporting — ideal for R&D validation, production testing, or pre-dispatch inspection.

Located in India, we cater to industries nationwide, offering convenient sample submission, pickup options, and remote consultations.

Here’s how we typically conduct a paint impact test at Kiyo R&D Lab:

Not all coatings behave the same way under stress. Several factors affect how well a paint withstands impact:

At Kiyo R&D Lab, we not only test your coatings but also help diagnose failure causes so you can improve future formulations or processes.

Our paint impact test services support multiple industries where coating strength and flexibility are crucial:

Wherever paint protection matters, Kiyo R&D Lab ensures it’s tested for real-world durability.

To make sure your coating test results are accurate and consistent, follow these steps before submission:

Our team will handle the rest — from conditioning to final analysis.

✅ Reliable, standards-based testing

✅ Insightful root-cause analysis

✅ Quick turnaround time

✅ Competitive pricing

✅ Trusted by OEMs, universities, and R&D teams across India

By choosing Kiyo R&D Lab, you’re not just getting test results — you’re gaining a partner in quality assurance.

A beautiful paint finish means nothing if it can’t endure real-world impact. Ensuring your coatings stay tough and flexible under stress is key to delivering products that last longer and perform better.

With Paint Impact Test Services in India – Kiyo R&D Lab, you get access to expert testing, detailed insights, and data you can trust. Whether you’re developing a new paint formulation, validating a vendor’s coating, or conducting regular QC checks — Kiyo R&D Lab is your reliable partner in coating durability testing.

🎯 Test. Validate. Improve.

Your coatings deserve nothing less.