Reliable Fatigue Testing Lab Services in chennai – Kiyo R&D Lab

Imagine a critical component—a connecting rod in a diesel engine, a crucial bolt in a railway track, or a bracket holding an LED screen on a moving vehicle. It looks perfectly fine, yet after months of constant operation, it suddenly snaps. The culprit is not a single, massive force, but the accumulation of damage from millions of tiny, repeated stress cycles. This insidious process is known as Fatigue.

Fatigue is the single leading cause of failure in engineered structures and components worldwide. It’s the slow, progressive wear that happens when materials are subjected to cyclic loading (repeated bending, pulling, or twisting). For manufacturers in India—especially those supplying high-stakes sectors like automotive, aerospace, and defense—ignoring fatigue means risking catastrophic failure, costly recalls, and reputation damage.

That’s why reliable, NABL-accredited fatigue testing services in india – Kiyo R&D Lab are an indispensable partner. We provide the scientific evidence needed to predict a product’s true lifespan, ensuring your components are designed not just for strength, but for enduring reliability.

Fatigue testing is the laboratory process of determining how long a material or component will survive when subjected to repetitive, fluctuating forces that mimic its real-world operational life.

Think of it as putting a part through several years of its intended use—a million stress cycles or more—in a compressed timeframe (often days or weeks). The entire point of the test is to understand how the material behaves at stress levels far below its ultimate tensile strength.

If an engineer only tests for static strength, the product may fail in the field prematurely because the design didn’t account for the slow growth of micro-cracks under repeated stress.

The demand for rigorous fatigue testing services in india is accelerating due to several modern engineering realities:

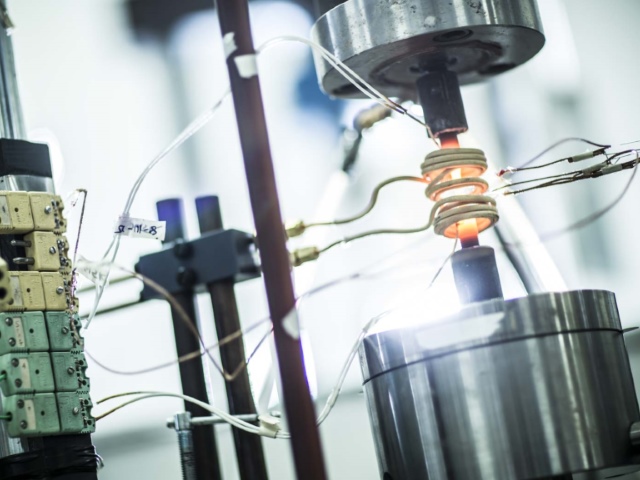

Kiyo R&D Lab utilizes specialized, high-capacity electromechanical systems to simulate various real-world stresses. When you choose fatigue testing lab services in india – Kiyo R&D Lab, you gain access to internationally standardized test types:

Choosing a partner for fatigue testing lab services in india requires certified expertise, as the accuracy of the result relies entirely on precise load control and measurement over millions of data points.

Kiyo R&D Lab is NABL-accredited (ISO/IEC 17025). This is the highest assurance of quality, guaranteeing that our load measurement, cycle counting, and reporting methods are traceable, reproducible, and accepted by regulatory bodies and global OEMs worldwide.

We utilize modern, electromechanical testing frames designed for high-frequency, high-precision cycling. This infrastructure is non-negotiable for generating reliable S-N curves, which form the basis of all modern endurance analysis.

When a component fails, our job isn’t done. Our expert engineers and metallurgists analyze the fracture surface to determine the root cause, crack initiation site, and propagation speed. This Failure Analysis and Consultation guides your design team to the most effective solution, saving iterative development time and cost.

We understand that fatigue often interacts with other factors like corrosion and temperature. Kiyo R&D Lab offers integrated services, allowing clients to test fatigue alongside thermal aging or material characterization under one roof.

In the competitive global market, static strength is just the beginning. The true measure of quality is endurance. Relying on untested materials for cyclic applications is a gamble that eventually leads to critical failures and reputational harm.

By partnering with fatigue testing lab services in india – Kiyo R&D Lab, you make a strategic investment in verified durability. You gain the assurance that your products will not just survive initial pressures, but will withstand the entire, stressful duration of their working life.

Ready to determine the true lifespan of your critical components? Contact Kiyo R&D Lab today to schedule your comprehensive fatigue testing.