At Kiyo R&D Center & Laboratory, we prioritize precision and accuracy in material testing to ensure that our clients receive reliable data for their products. One of the critical tests we conduct is the ASTM D 2240 Standard Test Method for Rubber Property—Durometer Hardness. This method is essential for understanding the hardness of rubber and elastomers, which impacts their performance in various applications.

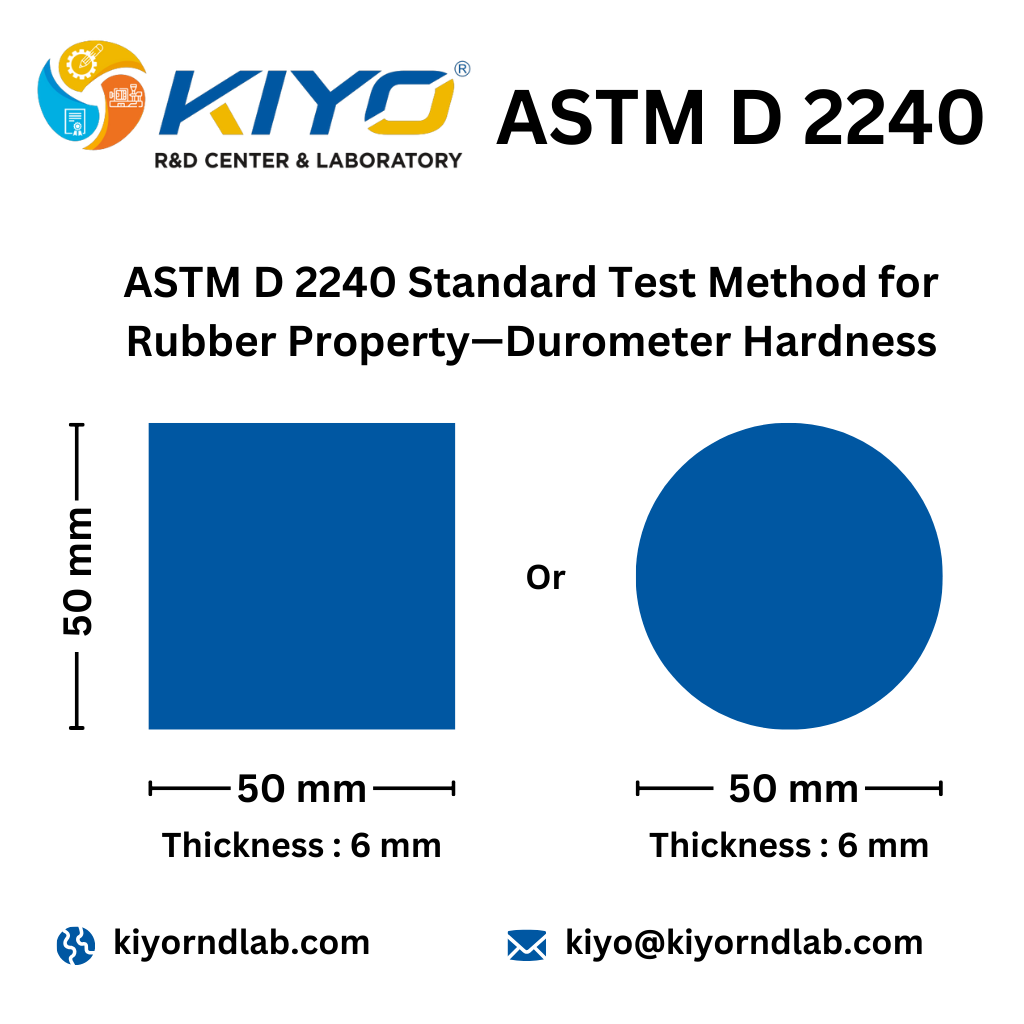

The ASTM D 2240 standard outlines the procedure for measuring the hardness of rubber and elastomeric materials using a durometer. A durometer is an instrument designed to indent the material’s surface and measure its resistance to deformation. This resistance is recorded as a hardness value, which helps in assessing the material’s rigidity and suitability for specific uses.

Durometer hardness testing plays a crucial role in several areas:

At Kiyo R&D Center & Laboratory, our durometer hardness testing involves the following steps:

Durometer hardness testing is essential in various industries:

At Kiyo R&D Center & Laboratory, we continuously invest in advanced testing technologies to enhance the precision and reliability of our durometer hardness tests. Our modern facilities and skilled technical team ensure we deliver accurate and consistent results, empowering our clients to make informed decisions about their materials and products.

The ASTM D 2240 Standard Test Method for Rubber Property—Durometer Hardness is a critical tool for evaluating the hardness and performance of rubber and elastomeric materials. Kiyo R&D Center & Laboratory is dedicated to upholding this standard, providing high-quality testing services that help our clients achieve their objectives and maintain a competitive edge.

Discover more about our durometer hardness testing services and their benefits by exploring our website or consulting with our expert team. Together, we can ensure the reliability and excellence of your rubber materials and products.

For quotation or visit